Volume

A volume corresponds to one

casting or is a void used to chamfer or make a hole in another volume.

There are 4 ways to specify

the geometry of a volume:

1. As a prism between 2 cross-sections

placed respectively at t = 0 and at t = "Length in t-direction". Using cross sections

2. Loading of STL-files in binary or

text format (ASCII). Loading STL Model

3. As a confined space defined by its

surfaces. Surface model

4. As a confined space defined by its edges. Edge Model

It is also possible to copy volumes

based on cross sections or STL Model to a Surface or Edge Model. This allows

you to customize the model beyond what the cross-sectional model or STL model

allows.

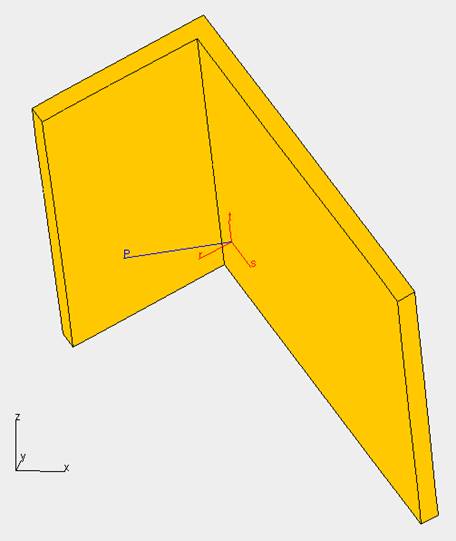

Positioning

The volume is positioned by specifying:

- the origo

of the local (r,s,t)-system in the global (x,y,z)-system.

- the direction of t-axis

in the (x,y,z)-system.

- the rotation of the (r,s,t)-system around the t-axis. This is done by specifying

the "Direction point", P. The (r,s,t)-system

is rotated around the t-axis in such a way that the direction point P is in the

r-t-plane, with a positive r-coordinate.

Origo of (r,s,t): (x,y,z)=(1.0, 1.0, 1.0);

t-vector: (x,y,z)=(0.0, -1.0, 1.0); Direction Point,

P: (x,y,z)=(0.5, 0.5, 1.0);

If volumes (which not are

voids) are intersecting, the software asks for information about which volume

is dominant and which is submissive.

Parameters

The volume can be defined

as being a void. The void can intersect more massive volumes.

Voids are useful to make

holes and to make chamfers (convex or concave) on non-prismatic volumes.

A massive volume needs a

reference to an earlier defined material.

The temperature of the

fresh concrete and the time of casting are assigned to the volume.

Al least one volume should

be defined from the beginning (Time = 0).

The material properties of

hardening concrete are described as a function of maturity. If the maturity of

the fresh concrete when casting, is significantly different from the starting

point of the function (this is often the time of mixing), then an initial

maturity can be indicated. This can apply in situations with a long transport

time. The initial maturity is calculated by hand using the formulas in EditMaterial on the time period before casting.

(Hint: The use of the

initial maturity increases the consistency between the simulation and the real

hardening process. The initial maturity is useful when e.g., having a daily

variation in the boundary conditions or changes in the curing measures at

specific times. Also, when monitoring temperatures, the use of initial maturity

may lead to a better agreement with the simulation. Furthermore, the initial

value can also include a contribution from the time used to place the concrete

in the volume.)

The variation of

temperature, maturity and stress is assumed to be parabolic within each element

(tetrahedron). Therefore, the user shall compare the fineness of the mesh with

the variation of the temperature/stress-field he/she wants to determine.

If the mesh is too coarse iso-lines

are not smooth. In that case the structure should be re-meshed with smaller

element-size. However, it should be noted that differences in material

properties and concrete age mean that the iso-lines across construction joints

do not have to be smooth.

The fineness is defined by

the size of the elements at the surface of the volume and the

distribution of the fineness towards the core is described by the gradient defined

in the “Setup window”.

Volumes in which there are

slight variations in temperatures, maturities and stresses can be satisfied

with a coarse network (e.g., former hardened concrete volumes and large

soil-volumes). If "Coarse Mesh" is checked, the mesh-generator will

make a coarse mesh, however under consideration to adjacent structural parts.

If “Self-Weight released

at” is checked, it is possible to indicate when the self-weight of the volume

is released. This is typically when the formwork is released. The direction of

gravity is the opposite direction of the zenith-direction defined in the

“Setup” window. When using this facility, it is necessary to define supports or

apply external loads which are equilibrating the self-weight, because automatically

generated supports are leading to inconvenient results. Read about supports and external loads.

If “Remove volume at” is

checked, it is possible to define a time for removal of the volume.

The volume can be deleted.

Trouble-shooting

If a hole is identical to a

portion of a massive volume, the software may fail.

The problem can be solved

by increasing the size of the hole.

If the corners of a volume

are touching another volume on a sloped surface, it could be necessary to

increase the number of decimals to establish the construction joint

properly.